In the same section

Sino-French Institute of Computing Technology for Advanced Materials (CTAM)

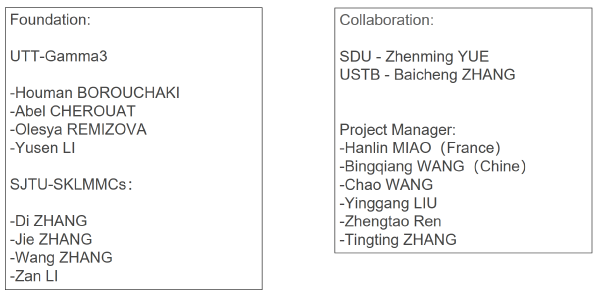

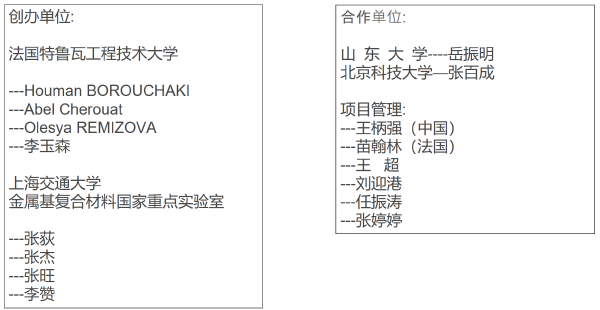

Scientific laboratory between UTT/GAMMA3 and SJTU/SKLMMCs

- CTAM (english version)

-

About CTAM

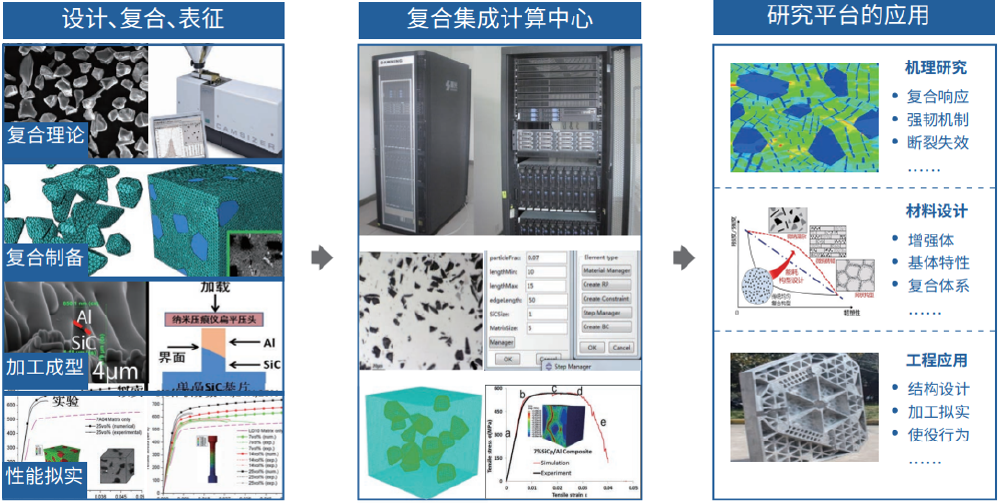

Sino-French Institute of Computing Technology for Advanced Materials (CTAM) focuses on the modelling and simulation for advanced material. The numerical tools will be developed for the application of advanced material in various components in the procedures of design, simulation, fabrication and inspection. And the integrated structure-function design platform will be developed for advanced material and a digital solution for the intelligent design-manufacturing-testing will be supported for intelligent manufacturing of the various components. The CTAM is well supported by advanced modelling technologies and numerical simulation tools in UTT/GAMMA3, and the advanced material preparations technologies and material test in SJTU/SKLMMCs.From 2019, there are more than 10 world wide expertise, such as the Academicians of European Academy of Sciences, other experts in the filed.We are focus on four topics, such as Adaptive remeshing technology, Ccoupled Behavior of Material, Numerical Simulation of Composites, and applications with the technology of modelling,simulation and Artificial Intelligent. There is a inner bourse to support the Engineering/PhD students. In 2022, we have 4 PhD students and more than 30 engineers covering mathematics, information, Multi-physics, computers, materials and applications. The technical supports and engineering services for mechanical design and lightweight design in the field such us automobiles, and for the digital twin in the field such as the power, energy, water conservancy.

iug

News (click to read)

Members and partners

j Key customers

2

Research institutesjk

Research Topicsujiokl

Research Direction 1Adaptive Remeshing Technology

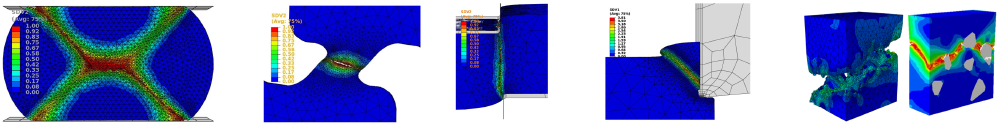

Based on the 2D/2.5D/3D adaptive remeshing algorithm, the tools have the abilities of geometrical error estimator(H1), physical error estimator (H2)and damage error estimator(H3), or the mixed mesh size and mesh quality control strategy(H=H1∩H2∩H3).

H1:The mesh with high quality is generated adaptively according to the geometric curvature and contact relationship. This is helpful to develop the smart preprocessing tool for finite element model.

H2:According to the calculation results and different physical fields, the mesh quality and mesh size is updated dynamically, which allows the mesh flows and supports large deformation analysis.

H3:The mesh is refined and deleted adaptively according to the damage factor, which is powerful in simulate the generation of crack and fracture.

ij

uiol

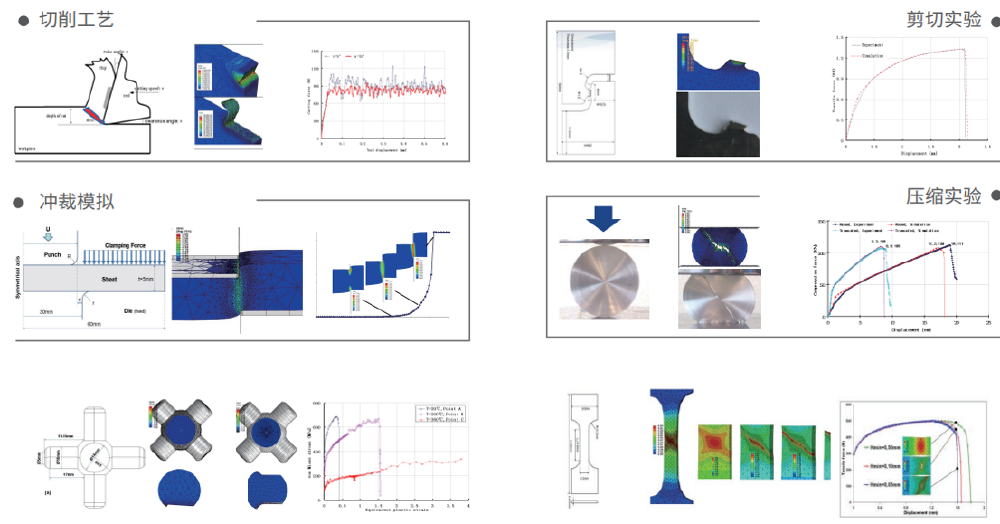

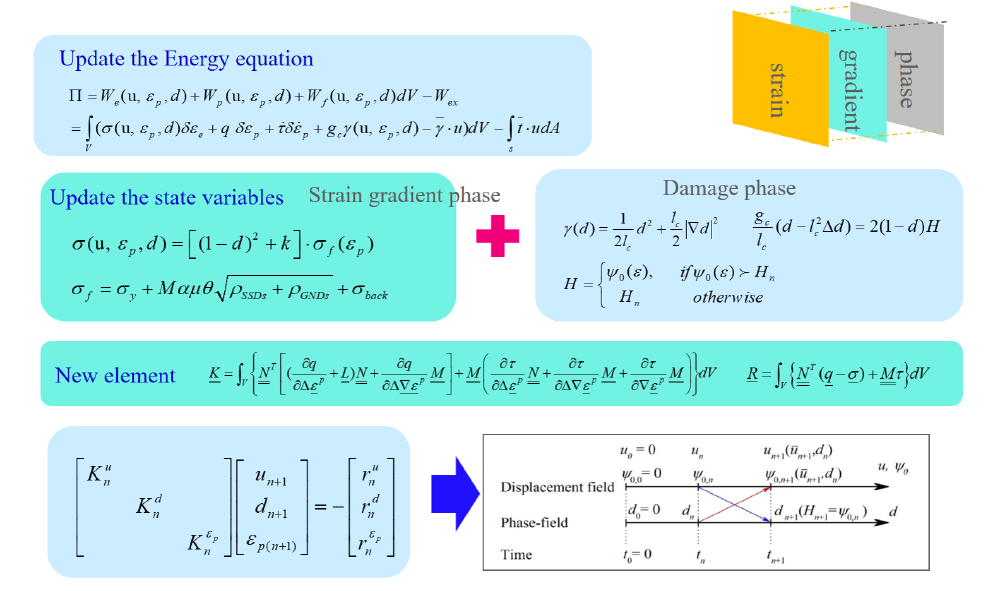

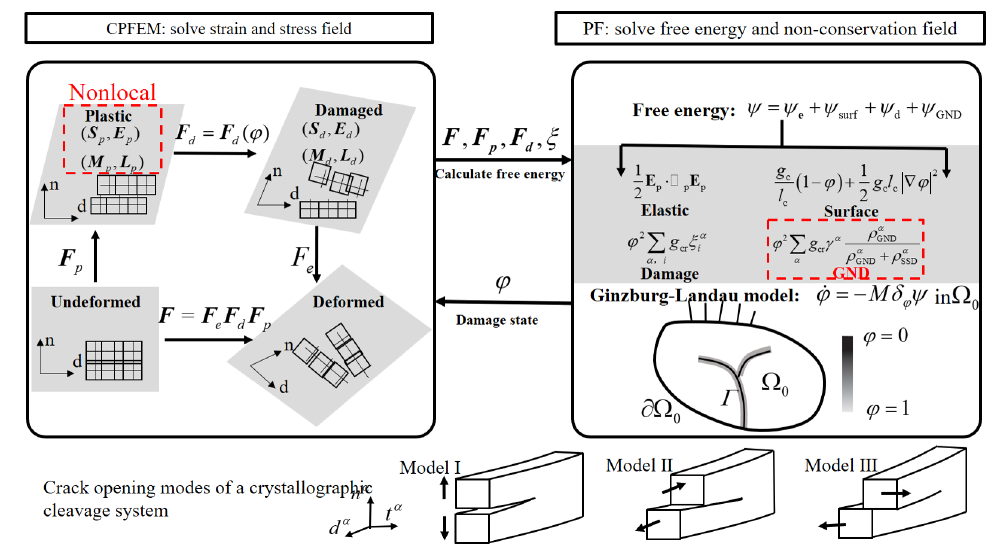

Research Direction 2Coupled constitutive equation for materials

- The rate-dependent crystal plasticity and strain gradient plasticity constitutive model considering the effect of deformation gradient;

- The constitutive model considering the influence of Load parameter, which involves the initial anisotropy, isotropic, kinematic hardenings and isotropic ductile damage;

- Multi-scale modeling considering stress triaxiality, Lode angle and growth rate of shear-reinforced porous and distribution of the stress-strain, dislocation density.

kg

jyfd

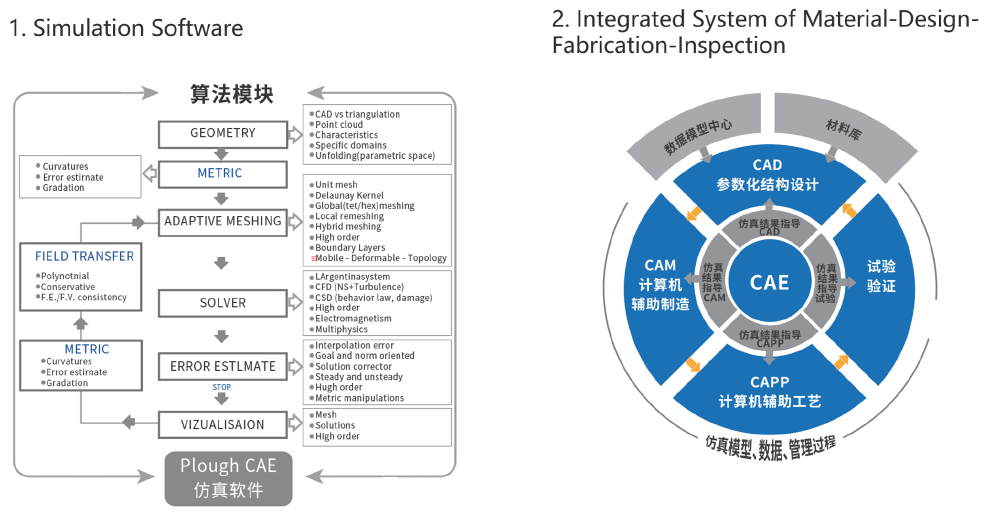

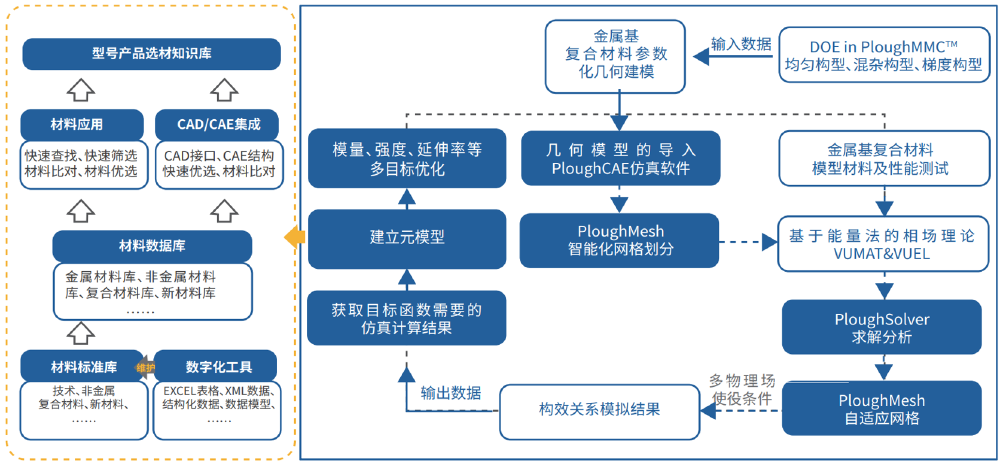

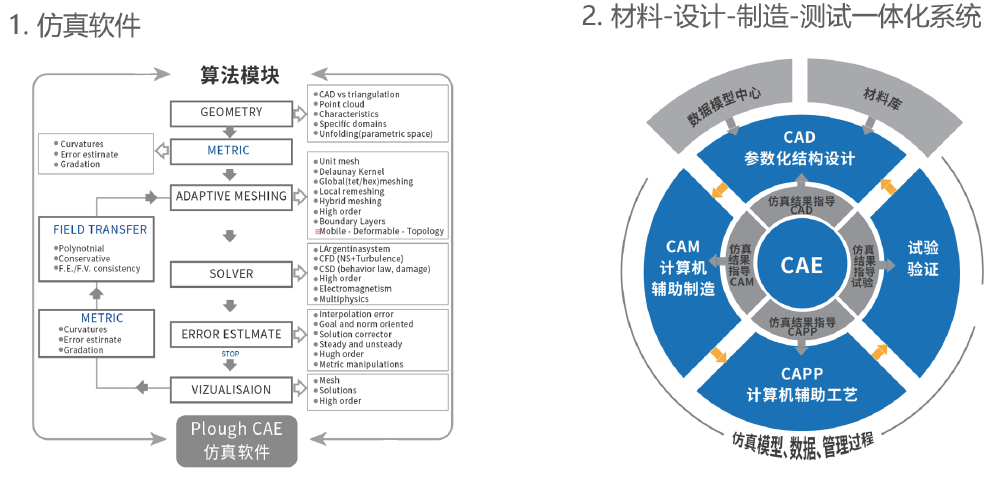

Research Direction 3Integrated system of material-design-manufacturing-test

- Software system: virtual simulation capability of materials from design to application;

- Main functions: geometric modeling, mesh processing, multi-physical analysis, multi-objective optimization, and life-cycle management;

- Materials: Metal matrix composites, Resin matrix composites, photo-electric and other functional materials,

gf

yfyi

jfyi Research Direction 4

Intelligent equipment

- Metal forming: bending, sheet forming, forging, casting, cutting, etc;

- Composite: automatic fibre laying, thermosetting, thermoplastic, etc;

- Intelligent detection: 3D detection of mobile phones, robots and unmanned aerial vehicles based on Lidar or vision;

- Test: components, microstructure, crystalline structure, micro-nano/macro tensile, fatigue, thermal and other strength tests.

-tèy_ui

Science projectsFirst step : from 2021 to 2023

· Academic research: multi-scale simulation for metal and matrix composites, resin matrix composites, photo-electric and functional materials.

· Student training: 1-2 doctoral candidates each year.

· Talent training: Sino-French post-doctoral workstation and 1-2 postdoctoral positions each year.

· Project cooperation: application of Sino-French scientific research projects.

·International exchange: twice a year, organize academic seminars in China and France, and build a international research center for multi-scale composite materials.Second step : from 2024 to 2028

· Algorithm development: Algorithm and integration of material-design-manufacturing-inspection system.

·Manufacturing equipment: Advanced manufacturing equipment of composite materials based on modeling and simulation.

· Inspection equipment: Intelligent inspection equipment of parts based on 3D modeling technology, 3D vision technology and robot system.

· Digital Twin: build the life-cycle management system based on modeling and simulation for design, manufacturing, operation and maintenance in smart manufacturing, power energy, infrastructure and other fields.Third step : from 2029 to 2031

· Industrial Park: establish an industrial park of advanced materials, industrial software and intelligent equipment.

· International R&D center: based on the UT-INSA/CSC project and the CTAM institute, built an international R&D center for multi-scale composite with the collaboration with the famous universitas, such as Northwestern Polytechnic University, Xi'an Jiaotong University, Chang'an University, Shandong University, Beijing University of Science and Technology, and so on.

· Sino-France cooperation: promote comprehensive cooperation between China and France in the fields of advanced materials, industrial software and intelligent equipment.

Papers

[1]BOROUCHAKI H, FREY P J. Adaptive triangular–quadrilateral mesh generation [J]. International Journal for Numerical Methods in Engineering, 1998, 41(5): 915-34.

[2]BOROUCHAKI H, GROSGES T, BARCHIESI D. Enhancement of the accuracy of numerical field computation using an adaptive three-dimensional remeshing scheme [J]. Comptes Rendus Mécanique, 2010, 338(3): 127-31.

[3]BOROUCHAKI H, LAUG P, CHEROUAT A, et al. Adaptive remeshing in large plastic strain with damage [J]. International Journal for Numerical Methods in Engineering, 2005, 63(1): 1-36.

[4]CHEROUAT A, BOROUCHAKI H, ZHANG J. Simulation of sheet metal forming processes using a fully rheological-damage constitutive model coupling and a specific 3D remeshing method [J]. Metals, 2018, 8(12): 991.

[5]FREY P J, BOROUCHAKI H, GEORGE P-L. 3D Delaunay mesh generation coupled with an advancing-front approach [J]. Computer methods in applied mechanics and engineering, 1998, 157(1-2): 115-31.

[6]FU X, TAN Z, MIN X, et al. Trimodal grain structure enables high-strength CNT/Al-Cu-Mg composites higher ductility by powder assembly & alloying [J]. Materials Research Letters, 2021, 9(1): 50-7.

[7]LI Y, LI A, YUE Z, et al. Springback prediction of AL6061 pipe in free bending process based on finite element and analytic methods [J]. The International Journal of Advanced Manufacturing Technology, 2020, 109(7): 1789-99.

[8]LI Z, ZHANG Y, ZHANG Z, et al. A nanodispersion-in-nanograins strategy for ultra-strong, ductile and stable metal nanocomposites [J]. Nature communications, 2022, 13(1): 1-13.

[9]LIN G, PENG Y, LI Y, et al. Remarkable anisotropic wear resistance with 100-fold discrepancy in a copper matrix laminated composite with only 0.2 vol% graphene [J]. Acta Materialia, 2021, 215(117092.

[10]LING X, WANG K, ZHANG W, et al. Bio-inspired, bimetal ZIF-derived hollow carbon/MXene microstructure aim for superior microwave absorption [J]. Journal of Colloid and Interface Science, 2022, 625(317-27.

[11]SADEGHI B, TAN Z, QI J, et al. Enhanced mechanical properties of CNT/Al composite through tailoring grain interior/grain boundary affected zones [J]. Composites Part B: Engineering, 2021, 223(109133.

[12]SU Y, LI Z, YU Y, et al. Composite structural modeling and tensile mechanical behavior of graphene reinforced metal matrix composites [J]. Science China Materials, 2018, 61(1): 112-24.

[13]TENG H, TAN Z, ZHAO X, et al. Simultaneously enhanced strength and ductility in graphene nanosheet/Al-Cu-Mg nano-laminated composites by incorporating coarse domains [J]. Materials Research Letters, 2023, 11(2): 143-51.

[14]WANG G, OUYANG H, SU Y, et al. Heterostructured bulk aluminum with controllable gradient structure: Fabrication strategy and deformation mechanisms [J]. Scripta Materialia, 2021, 196(113762.

[15]WANG Y, TUOFU Z-M, YUE Z, et al. Research on adhesion strength and optical properties of SiC films obtained via RF magnetron sputtering [J]. Chinese Journal of Physics, 2020, 64(79-86.

[16]ZHANG J, OUYANG Q, GUO Q, et al. 3D Microstructure-based finite element modeling of deformation and fracture of SiCp/Al composites [J]. Composites Science and Technology, 2016, 123(1-9.

[17]ZHANG Z, YUE Z, BAO Y, et al. Strain ratio effects on microstructure discovery and low-cycle fatigue behavior of DP600 steel under cyclic shear path [J]. Materials Science and Engineering: A, 2022, 830(142291.

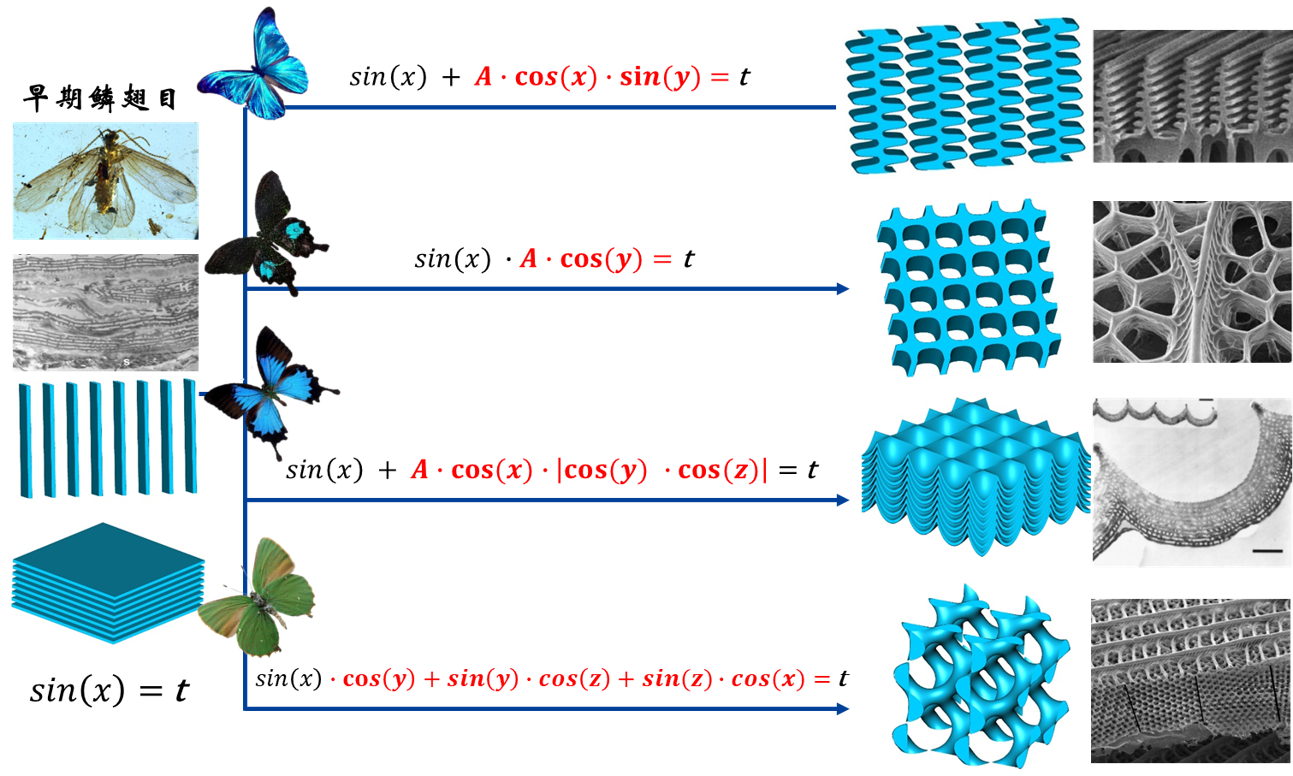

[18]ZHAO X, WANG W, ZHANG W, et al. Optical Optimization with Microstructure Evolution Inspired from Lepidopteran Scales [J]. Advanced Optical Materials, 2022, 2200710.

[19]ZHU S, BOUBY C, CHEROUAT A, et al. 3D reconstitution and numerical analysis of superelastic behavior of porous shape memory alloy [J]. International Journal of Solids and Structures, 2019, 168(109-22.

[20]ZHU S, CHEROUAT A, BOROUCHAKI H. Inverse engineering for innovate material: 3D reconstitution and simulation of aluminum foams [J]. IFAC-PapersOnLine, 2016, 49(12): 979-83.

- CTAM (chinese version)

-

关于CTAM

中法先进材料计算技术研究院(CTAM)依托法国特鲁瓦工程技术大学UTT/GAMMA3实验室的先进建模和仿真技术,以及上海交通大学金属基复合材料国家重点实验室的先进材料制备和检测设基础,致力于先进材料的设计、仿真、制造和检测过程中的几何建模、仿真验证和工业软件的开发,为新材料的应用提供结构-功能一体化设计平台和零部件的研发-制造-检测智能化制造的数字化解决方案。

2019年设立以来,已经建立了一支拥有10余位以欧洲科学院院士和中法一级教授为主的国际化技术骨干团队,技术面涵盖数学、力学、多物理场、计算机、先进材料等领域,具有自适应网格的重构和材料耦合的本构技术,以及针对新材料应用的结构-功能一体化的设计软件和面向零部件的全生命周期管理的数字孪生平台。研究院具有长效的高层次人才培养体系,截止2022年,培养了4名博士生和30多名工程师,为航空航天、汽车船舶等领域的结构轻量化设计,以及电力能源、基础设施等领域的数字孪生提供工业软件和技术咨询。

jytdeu 关于 CTAM 的新闻

团队组成

fdghj 主要客户

2

研究机构jk

仿真软件t

研究方向一优势一、自适应网格重构技术

基于2D/3D的网格自适应生成算法,具有几何误差估计(H1)、物理误差估计(H2)和损伤误差估计(H3)的独立或交叉的全局网格尺寸和网格质量的智能控制策略(H=H1∩H2∩H3)。

lH1: 根据几何曲率和接触关系自适应地生成规则网格,具有接触关 系自动定义功能,支持几何前处理的自动化有限元建模;

lH2:根据计算结果和不同物理场自适应生成规则网格,具有单元动 态更新和优化功能,支持网格流动等大变形分析;

lH3:根据断裂损伤因子自适应地细化网格,具有全局网格优化和单 元自动删除功能,支持裂纹生成等过程分析。

ij

uiol

研究方向二优势二、材料的耦合本构技术

晶粒模拟:耦合变形梯度影响的晶体塑性和应变梯度塑性的材料本构模型 ;

损伤行为:耦合损伤的各向异性、各向同性、运动硬化等的材料本构模型;

使役条件:耦合应力状态(三轴应力和Lode角)、热应力、疲劳应力等的材料本构模型

kg

jyfd

研究方向三优势三、材料-设计-制造-测试一体化技术

软件系统:构建材料从设计到应用的全流程虚拟仿真能力

主要功能:参数化几何建模、自动化网格处理、多物理场仿真分析、多目标参数优化、全生命周期管理

适用材料:金属及基复合材料,树脂及其复合材料,光电等功能材料

gf

yfyi

jfyi 研究方向四

优势四、材料-设计-制造-检测一体化装备研发

金属成型:弯管、薄板成型、锻造、铸造、切削等

复材工艺:自动铺丝、热固性、热塑性等

智能检测:基于激光雷达和视觉的手机、机器人和无人机等的3D检测

材料测试:组分测试、微观结构、晶相组织、微纳/宏观的拉伸、疲劳、热力等强度测试

sdfo

项目计划第一步:2021 – 2023

·学术研究:金属及基复合材料,树脂及其复合材料,光电等功能材料多尺度模拟;

·学生培养:每年联合指导1-2名博士研究生,提供UTT或SJTU学位;

·人才培养:建立中法博士后工作站,每年提供1-2名博士后职位;

·项目合作:联合申请和完成中法科研项目;

·国际交流:每年2次国际交流,在中国和法国共同组织学术研讨会,共建多尺度复合材料国际联合研究中心。第二步:2024 – 2028

·算法开发:材料-设计-制造-检测一体化系统地核心算法研究;

·制造装备:复合材料的基于建模和仿真系统的先进工艺和制造装备研究;

·检测装备:零部件的基于3D建模技术、3D视觉技术和机器人的智能化检测装备研究;

·数字孪生:构建面向高端制造和电力能源、基础设施等领域的基于建模和仿真的设计、制造和运维的全生命周期管理系统。第三步:2029 – 2031

·产业基地:面向中国市场建立先进材料、工业软件和智能装备的产业基地;

·研发中心:基于UT-INSA/CSC 项目以及CTAM的研发基础,与西北工业大学、西安交通大学、长安大学、山东大学、北京科技大学等联合共建研发中心,建成多尺度复合材料国际联合研究中心

·中法合作:促进中法在先进材料、工业软件和智能装备等领域的全面合作。参考论文

[1]BOROUCHAKI H, FREY P J. Adaptive triangular–quadrilateral mesh generation [J]. International Journal for Numerical Methods in Engineering, 1998, 41(5): 915-34.

[2]BOROUCHAKI H, GROSGES T, BARCHIESI D. Enhancement of the accuracy of numerical field computation using an adaptive three-dimensional remeshing scheme [J]. Comptes Rendus Mécanique, 2010, 338(3): 127-31.

[3]BOROUCHAKI H, LAUG P, CHEROUAT A, et al. Adaptive remeshing in large plastic strain with damage [J]. International Journal for Numerical Methods in Engineering, 2005, 63(1): 1-36.

[4]CHEROUAT A, BOROUCHAKI H, ZHANG J. Simulation of sheet metal forming processes using a fully rheological-damage constitutive model coupling and a specific 3D remeshing method [J]. Metals, 2018, 8(12): 991.

[5]FREY P J, BOROUCHAKI H, GEORGE P-L. 3D Delaunay mesh generation coupled with an advancing-front approach [J]. Computer methods in applied mechanics and engineering, 1998, 157(1-2): 115-31.

[6]FU X, TAN Z, MIN X, et al. Trimodal grain structure enables high-strength CNT/Al-Cu-Mg composites higher ductility by powder assembly & alloying [J]. Materials Research Letters, 2021, 9(1): 50-7.

[7]LI Y, LI A, YUE Z, et al. Springback prediction of AL6061 pipe in free bending process based on finite element and analytic methods [J]. The International Journal of Advanced Manufacturing Technology, 2020, 109(7): 1789-99.

[8]LI Z, ZHANG Y, ZHANG Z, et al. A nanodispersion-in-nanograins strategy for ultra-strong, ductile and stable metal nanocomposites [J]. Nature communications, 2022, 13(1): 1-13.

[9]LIN G, PENG Y, LI Y, et al. Remarkable anisotropic wear resistance with 100-fold discrepancy in a copper matrix laminated composite with only 0.2 vol% graphene [J]. Acta Materialia, 2021, 215(117092.

[10]LING X, WANG K, ZHANG W, et al. Bio-inspired, bimetal ZIF-derived hollow carbon/MXene microstructure aim for superior microwave absorption [J]. Journal of Colloid and Interface Science, 2022, 625(317-27.

[11]SADEGHI B, TAN Z, QI J, et al. Enhanced mechanical properties of CNT/Al composite through tailoring grain interior/grain boundary affected zones [J]. Composites Part B: Engineering, 2021, 223(109133.

[12]SU Y, LI Z, YU Y, et al. Composite structural modeling and tensile mechanical behavior of graphene reinforced metal matrix composites [J]. Science China Materials, 2018, 61(1): 112-24.

[13]TENG H, TAN Z, ZHAO X, et al. Simultaneously enhanced strength and ductility in graphene nanosheet/Al-Cu-Mg nano-laminated composites by incorporating coarse domains [J]. Materials Research Letters, 2023, 11(2): 143-51.

[14]WANG G, OUYANG H, SU Y, et al. Heterostructured bulk aluminum with controllable gradient structure: Fabrication strategy and deformation mechanisms [J]. Scripta Materialia, 2021, 196(113762.

[15]WANG Y, TUOFU Z-M, YUE Z, et al. Research on adhesion strength and optical properties of SiC films obtained via RF magnetron sputtering [J]. Chinese Journal of Physics, 2020, 64(79-86.

[16]ZHANG J, OUYANG Q, GUO Q, et al. 3D Microstructure-based finite element modeling of deformation and fracture of SiCp/Al composites [J]. Composites Science and Technology, 2016, 123(1-9.

[17]ZHANG Z, YUE Z, BAO Y, et al. Strain ratio effects on microstructure discovery and low-cycle fatigue behavior of DP600 steel under cyclic shear path [J]. Materials Science and Engineering: A, 2022, 830(142291.

[18]ZHAO X, WANG W, ZHANG W, et al. Optical Optimization with Microstructure Evolution Inspired from Lepidopteran Scales [J]. Advanced Optical Materials, 2022, 2200710.

[19]ZHU S, BOUBY C, CHEROUAT A, et al. 3D reconstitution and numerical analysis of superelastic behavior of porous shape memory alloy [J]. International Journal of Solids and Structures, 2019, 168(109-22.

[20]ZHU S, CHEROUAT A, BOROUCHAKI H. Inverse engineering for innovate material: 3D reconstitution and simulation of aluminum foams [J]. IFAC-PapersOnLine, 2016, 49(12): 979-83.